Whether you are new to working with clutches or need help explaining how a clutch works, the following information will help you better understand how the clutch system and its various components work.

Key Components:

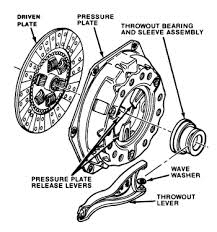

- Clutch (sometimes called the pressure plate)

- Disc

- Flywheel

- Release Bearing

- Release System (hydraulic, mechanical or cable)

The clutch disc or driven member is basically a steel plate, covered with a frictional material that goes between the flywheel and the pressure plate. In the center of the disc is the hub, which is designed to fit over the splines of the input shaft of the Power Take Off. When the clutch is engaged, the disc is “squeezed” between the flywheel and pressure plate, and power from the engine is transmitted by the disc’s hub to the input shaft of the PTO.

In layman’s terms, a pressure plate is a spring-loaded “clamp,” which is bolted to the flywheel. It includes a sheet metal cover, heavy release springs, a metal pressure ring that provides a friction surface for the clutch disc, a thrust ring or fingers for the release bearing, and release levers. The release levers lighten the holding force of the springs when the clutch is disengaged. The springs used in most pressure plates are of a diaphragm-type, however a few use multiple coil springs.

The “throw-out bearing” is the heart of clutch operation. When the clutch hand lever is moved, the throw-out bearing moves toward the flywheel, pushing in the pressure plate’s release fingers and moving the pressure plate fingers or levers against pressure plate spring force. This action moves the pressure plate away from the clutch disc, thus interrupting power flow.

Pressure Plate Clamping Pressure

We stock clutch kits to suit your spring loaded Auto Clutch HD1300, The NACD, Twin Disc, Stein Manufacturing and WPT spring loaded, automotive style PTO’s . Our pressure plates are different from the standard clutch you might find at your local auto parts store, the clamping pressure is much higher, than the ” off the shelf clutch ” so while you may save money in the short run, it will cost you money in the long run.

Flywheel Resurfacing ( Grinder )

Proper resurfacing of the flywheel is critical to clutch operation. The flywheel must be resurfaced or replaced; failure to do so will void the warranty of the clutch set.

Caution:

Running the engine with the PTO dis-engaged for extended periods of time can cause failure of the throw-out bearing.

Engaging and disengaging the clutch at maximum engine RPM can cause the disc, pressure plate and throw-out bearing to overheat and can result in premature failure of these components. Properly disengaging the clutch and PTO is as important as the engagement.